Emma Simpson

Business correspondent

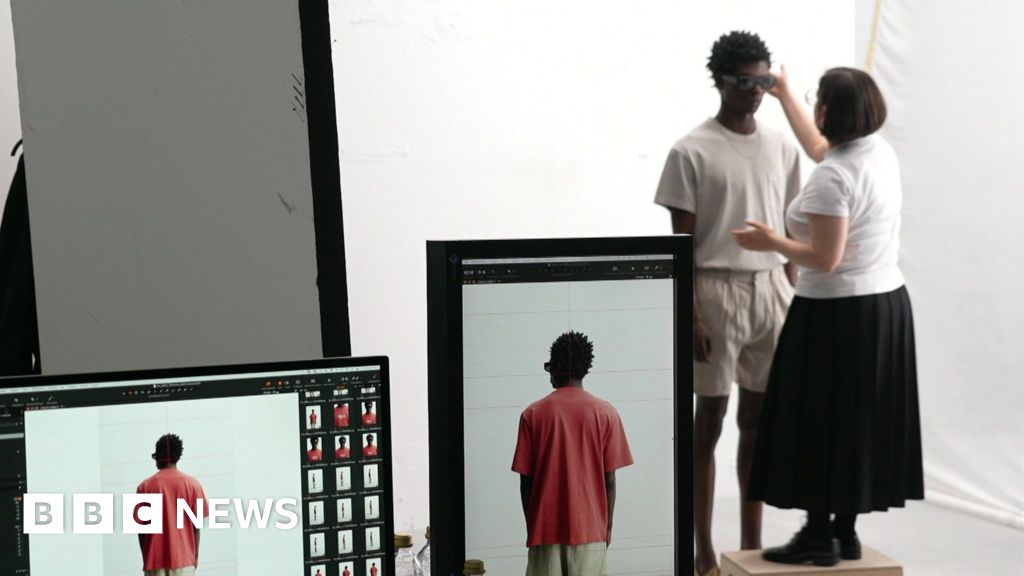

Watch: BBC exclusively granted behind the scenes access to Zara’s Spanish headquarters

It will be a very sexy summer, a romantic cowboy and rock and roll touch.

At least according to Mehdi Sousanne. And he should know. He is a designer for Zara and helps create clothing for one of the most successful stories in high street fashion: brands.

Zara is owned by Inditex, the world’s largest fashion retailer, running a series of store chains, including Massimo Dutti and Pull & Bear.

Although it relies on 1,800 suppliers around the world, almost all of its clothing is transported to Spain at the company’s base to ship to stores in 97 countries.

Zara doesn’t promote and rarely does interviews. However, as the first store has been in business for 50 years, I came to Galicia’s vast campus and met the bosses and workers to get a rare glimpse into how the secret brand operates.

The company not only has the growing competition between Sheen and Tem, an ultra-stable online player shipping directly from China, but it has also found that it has to navigate the rapidly changing market, as well as the uncertainty surrounding US tariffs.

But Inditex CEO Oscar Garcia Maceiras says that US President Donald Trump’s tariffs will not disrupt supply chains or change Zara’s plans to expand further in the US, the second largest market now.

“Leave in mind that diversification is important for us. We produce in almost 50 different markets with non-exclusive suppliers, so we are used to adapting to change,” he says.

Designer Mehdi Sousanne has worked at Zara for 11 years

Since the first store opened quickly by car in the town of Coruna, the business has certainly adapted and grown.

Currently, we have 350 designers and staff from around 40 countries.

“There’s no rules in general. It’s all about emotions,” says Mehdi, who is committed to delivering important pieces for the season.

He says inspiration comes from people ranging from “streets” to cinemas and catwalks. He likes to sketch his ideas once a very important mood board is created.

In the pattern cutting room, the design is transformed into a paper sample and is fixed to a mannequin. Dozens of tailors then run the first fabric sample on the spot and do the first fitting.

Pattern maker Mar Marcote has been in business for 42 years, but uses a magnifying glass to look up each item of clothing before it is finally produced.

“When you complete an item and make sure it can be sold out once it looks better, and that’s great,” she says.

Marmacote says she takes great pride in her work

Zara is a business that has changed the way you shop.

In the old days, retailers released two main collections of the year: Spring/Summer and Autumn/Winter. For decades, most chains have outsourced their manufacturing to low-cost factories in the Far East, with clothing arriving in up to six months.

Zara opposed traditional wisdom by bringing many of her clothes closer to her home and changing products more frequently. This means that they responded much faster to the latest trends and were able to drop new items into the store every week.

Half of that garment is made in Spain, Portugal, Morocco and Türkiye. There is a factory on the HQ site where small production is carried out, and is owned by seven more factories.

As a result, you can turn your product around in a few weeks.

Zara’s clothing inspiration can come from anywhere

More basic fashion staples are produced at longer lead times in countries such as Vietnam and Bangladesh.

Logistics and data are other factors behind its success. All clothing is packaged and dispatched from a distribution centre in Spain and a distribution centre in the Netherlands.

“What’s absolutely important is the level of accuracy,” says CEO Maceiras.

“It allows us to make the right decisions as last as possible, in order to adapt our fashion proposals to customer profiles from different locations and to properly assess the appetites from our customers.”

In other words, you will deliver the right product to the right store.

At its headquarters, product managers receive real-time data on how clothing is sold in stores around the world, and importantly, customer feedback is received, shared with designers and buyers, and adjust the range along the season as per demand.

Unlike other high street rivals, you will receive a discount only when you stage double the sales per year.

Zara’s boss says quality, creativity and sustainability are at the heart of brand offerings

But is Zara starting to lose its shine after slowing sales growth earlier this year?

“The key challenge for Inditex is that it continues to be relevant in the fashion world that continues to become faster and cheaper,” says William Woods, a European retail analyst at Bernstein.

Not only are mainstream rivals like H&M, Mango and Uniqlo catching up, but the market is also confused by Shein and Temu.

Shein won $38 billion in Global Sales last year. This is the whisker behind Inditex.

When asked how much of a threat to Zara Shane and Tem’s success poses, Matheilas emphasizes that their business model is price-independent.

“Of course, we are looking to provide our customers with affordable products. But for us, it’s important to provide our customers with fashion that should be quality, creativity and sustainably inspired.”

Zara has come a long way since founder Amancio Ortega started his business.

The company is still majority owned by his family, and his daughter Marta is now the chairman of the group.

Ortega, now 89, remains a well-known residence, but is still diving in.

“He is a being, a physical or moral being, absolutely every day.”